发布时间:2024-10-11 发布人:Delta Max Automation

New Frontiers in PLC Extension Models: Applications, Advancements, and Industry Impact

New Frontiers in PLC Extension Models: Applications, Advancements, and Industry Impact

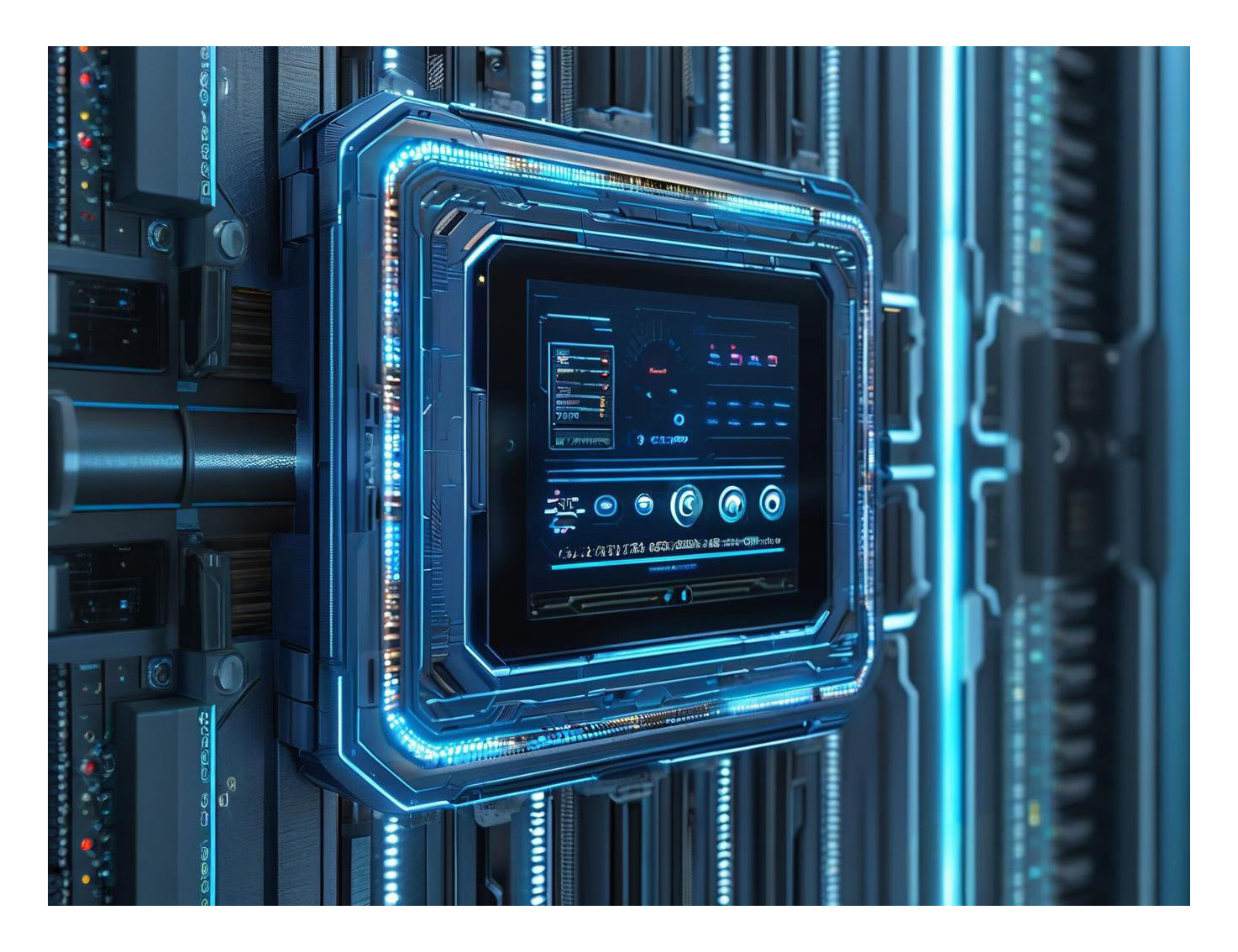

The latest developments in PLC extension models are pushing the boundaries of industrial automation by offering more powerful, flexible, and scalable solutions. These new models are designed to cater to the evolving needs of industries that require efficient, reliable, and adaptable control systems.

One of the most notable trends is the integration of advanced communication protocols in the latest PLC extension models. These models are now equipped with enhanced data transfer capabilities, allowing for faster and more secure communication between the PLC and other devices in the system. This is particularly beneficial in industries where real-time data monitoring and control are crucial, such as in manufacturing, energy management, and process automation. The ability to seamlessly connect to a wide range of devices, sensors, and actuators ensures more precise control and better system integration.

Another key development is the introduction of more modular and scalable PLC extension models. These models allow users to easily expand or reduce system capacity by adding or removing extension modules as needed. This scalability is essential for businesses that experience fluctuating demands or wish to gradually upgrade their automation systems without significant downtime. These extensions can be tailored to fit specific application needs, whether it’s for controlling complex machinery, managing production lines, or optimizing supply chains.

In terms of applications, these updated PLC extension models are seeing increasing use in sectors such as automotive, food and beverage, pharmaceuticals, and renewable energy. For example, in the automotive industry, they are used to control robotic arms and assembly lines, ensuring precision and efficiency in the manufacturing process. In food and beverage, PLC extensions help manage the automated production lines, ensuring consistent product quality and reducing waste. Additionally, in renewable energy, they are used to optimize the operation of wind turbines, solar panels, and energy storage systems, contributing to better energy efficiency and resource management.

These models are also being designed with improved durability and reliability, allowing them to function effectively in harsh industrial environments. Many of the new PLC extensions are capable of withstanding extreme temperatures, humidity, and vibrations, making them ideal for use in environments such as mining, oil and gas, and chemical processing plants.

Finally, the integration of advanced diagnostics and predictive maintenance features in the latest PLC extension models is helping businesses proactively monitor system performance. By providing real-time feedback and early warnings about potential failures, these extensions help prevent costly downtime and ensure smoother operations.

Overall, the advancements in PLC extension models are transforming automation systems, making them more versatile, efficient, and capable of meeting the complex needs of modern industries. Their applications across diverse sectors demonstrate their growing importance in optimizing production processes and ensuring high standards of quality and reliability.